An intelligent data driven approach for fault diagnosis in industrial machinery

Keywords:

Condition Monitoring, Fault Diagnosis, Vibration Analysis, Gear Hobbing, Mechanical Engineering, Smart Machine LearningAbstract

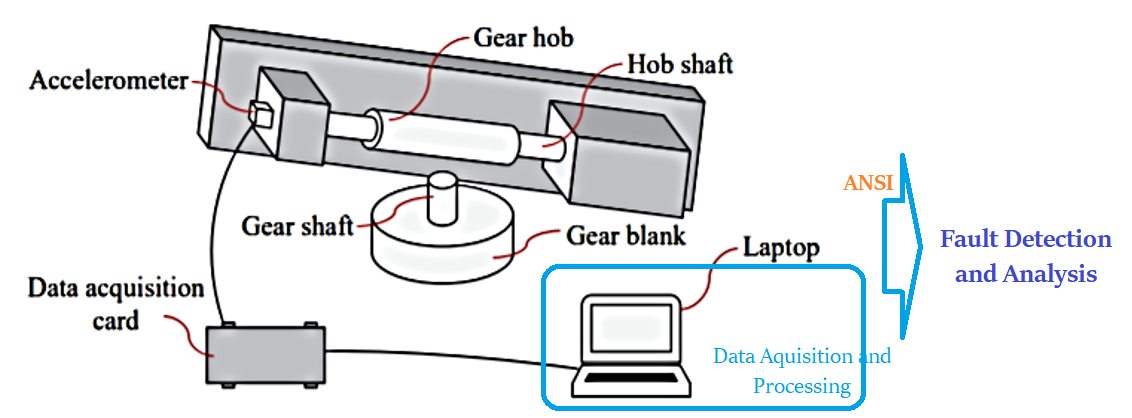

High-quality gears are exclusively produced by the hobbing process. Maintaining a competitive edge in the market involves producing quality gear at competitive prices. In the process of hobbing a gear, tremendous kinetic and rotational forces are generated. The downtime of the equipment is increased if even a minor flaw goes undetected and causes a catastrophic breakdown. This paper presents a novel method for fault diagnosis based on adaptive neuro-fuzzy inference systems (ANFISs). The method consists of three stages. Vibration signals are collected from an industrial gear hobbing machine. After pre-processing, feature extraction is performed on vibration signals to acquire more fault characteristic information. The salient feature sets are input into the ANFIS optimized with Particle Swarm Optimization (PSO) to identify different abnormal cases. The proposed method is applied to the fault diagnosis of gear hobbing machines, and the results demonstrate that the proposed system can reliably recognize different fault categories and has a better classification performance compared to other classifiers based on ANFIS.

URN:NBN:sciencein.jist.2023.v11.521

Downloads

Downloads

Published

Issue

Section

URN

License

Copyright (c) 2023 Himanshu Vasnani, Neeraj Kumar

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Rights and Permission