Prediction models for remaining life assessment of Pressure Vessels: A comparative analysis of inspection-based and chemical approaches

DOI:

https://doi.org/10.62110/sciencein.jist.2025.v13.1136Keywords:

Structural Integrity, Corrosion Rate Prediction, Fitness for service, Degradation Mechanisms, Pressure Vessel, Chemical EngineeringAbstract

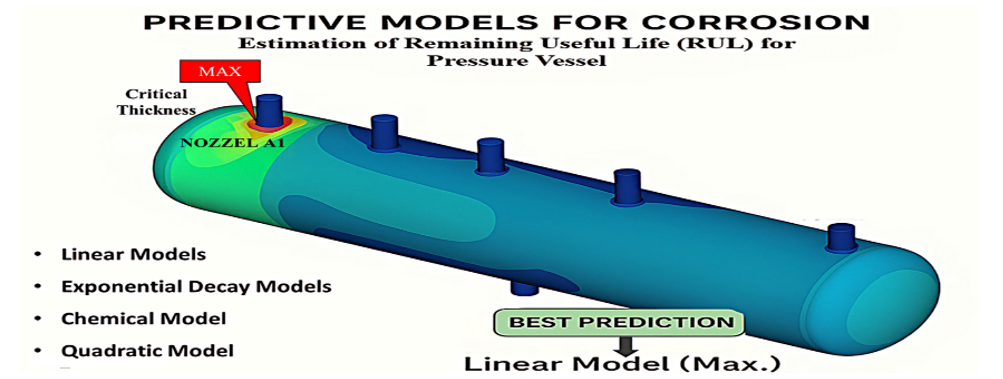

This study examines the effectiveness of various predictive models for estimating the remaining useful life (RUL) of low-alloy steel pressure vessels subjected to corrosion-induced metal loss. Using API 579-1/ASME FFS-1 standards, linear, nonlinear (quadratic, exponential decay), and chemical models were applied to ultrasonic thickness data collected between 2002 and 2008. The Linear Model (Max.) provided conservative estimates, predicting faster degradation compared to the Linear Model (Avg.), while the Quadratic Model indicated an accelerating corrosion rate unsuitable for most scenarios. Power and logarithmic models suggested negligible thickness changes over time, potentially underestimating real-world corrosion risks. The Chemical Model balanced simplicity and accuracy with moderate degradation predictions. Exponential Decay Models (Max. and Avg.) demonstrated decreasing corrosion rates over time, with the maximum variant offering more conservative predictions. Results showed that model selection significantly impacts RUL estimates: linear and chemical models are effective for short-term predictions, while exponential decay models are more accurate for long-term assessments. Critical sections such as Nozzles A1 and A2 were identified as high-risk areas requiring immediate attention. Finite Element Analysis (FEA) is recommended to assess structural integrity further, incorporating stress analysis to guide maintenance and repair strategies. This work provides a comprehensive framework for integrating inspection data, predictive modelling, and structural analysis to enhance safety and optimize maintenance in high-risk industries.

Downloads

Downloads

Published

Issue

Section

URN

License

Copyright (c) 2025 Mina A. Pascal, Timur Sultanmagomedov, Sultanmagomed Magomedtagirovich

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Rights and Permission